Notes from the Shore | Spring 2023

By Chris Barritt, Shoreside Support ManagerWhen our ships head out to sea for the first time in March it means kids are out having fun and our boats are doing what they were built for. In the shop it means it’s time to move on to keeping the boats supplied and to clean up from a winter’s work. This spring Gillian and Sam have been working on a new inventory system to help keep track of the many parts and spares that we have both on board and at the shop. I doubt there are many workshops that could match us for diversity of contents. A box of leather, a pallet of lifejackets, a spare alternator, baggywrinkle, spare parts for the water makers, three sextants, spare sails, the bending jigs for making mast hoops, mast hoops, a box of Christmas lights, signal flags, a woodworking shop, a forklift, a full lumber rack, and of course that nice piece of teak that’s an odd shape but is bound to be good for something sooner or later...needless to say, a step forward in inventory management will be a good thing.

We’ve made a few small improvements to the shop including some better storage, some upgrades to dust collection for the tools, some more lighting, and some accessories for the table saw.

During the spring sailing season, Mondays and Fridays tend to be busy with our schooners leaving and returning from their adventures so maintenance time is midweek, and on the weekends. That means we mostly shift to smaller projects on board that can be managed in a couple of days, and things that we can work on in the shop while the boats are out. Some of the smaller on-board projects have been some recaulking and deck-seam maintenance, and several small woodwork jobs to keep up with the wear and tear of daily use.

During the spring sailing season, Mondays and Fridays tend to be busy with our schooners leaving and returning from their adventures so maintenance time is midweek, and on the weekends. That means we mostly shift to smaller projects on board that can be managed in a couple of days, and things that we can work on in the shop while the boats are out. Some of the smaller on-board projects have been some recaulking and deck-seam maintenance, and several small woodwork jobs to keep up with the wear and tear of daily use.

|

|

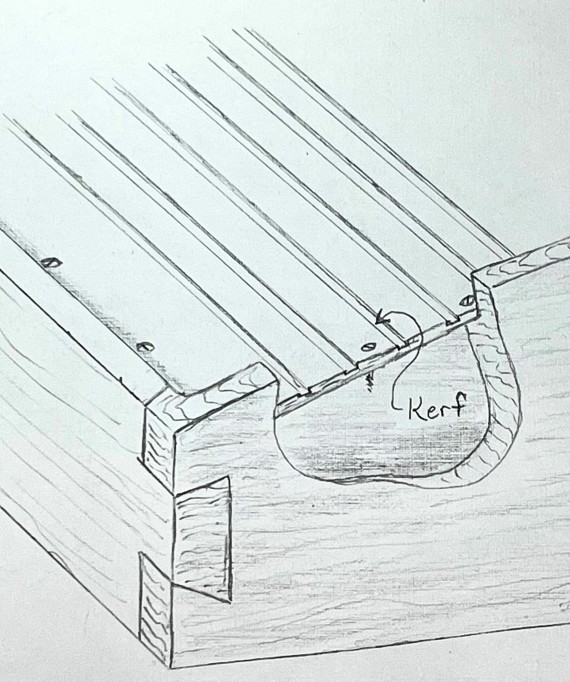

In the shop Patrick has been building two new deck boxes for the Pacific Swift which are almost complete. The older boxes had lids made of solid fir but now we make them with a base of marine plywood and thinner fir strips glued on top with epoxy. This has the advantage of making a stiffer and lighter lid. It also means we can use thinner pieces of fir which are easier to come by, often just using the offcuts from larger projects.

The corners of the boxes are joined with dovetails (my favorite part) and the picture shows the plywood base ready for the strips to be glued on top. The long cuts in the plywood are ‘kerfs’. These take some of the tension out of the plywood and allow it to bend smoothly with the curve. There’s a ledge cut into the inside of the lid where the plywood fastens down.

Our boats keep us busy!

The corners of the boxes are joined with dovetails (my favorite part) and the picture shows the plywood base ready for the strips to be glued on top. The long cuts in the plywood are ‘kerfs’. These take some of the tension out of the plywood and allow it to bend smoothly with the curve. There’s a ledge cut into the inside of the lid where the plywood fastens down.

Our boats keep us busy!

|

|

Photos by Chris Barritt